This piece announced as winner of the design and innovation award at the Double Take in Wood exhibition. Melbourne.

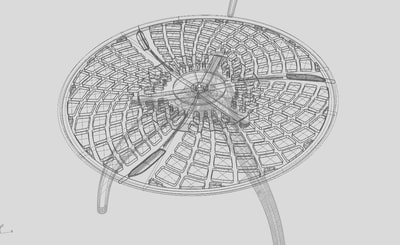

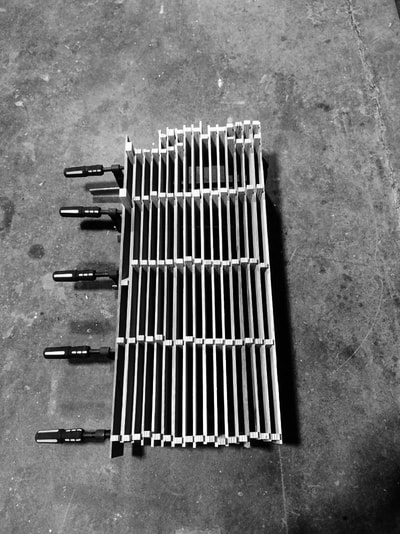

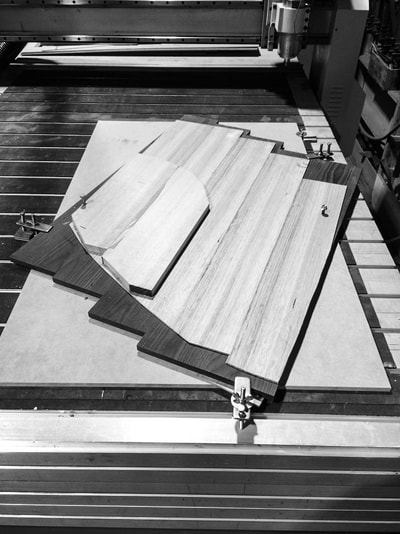

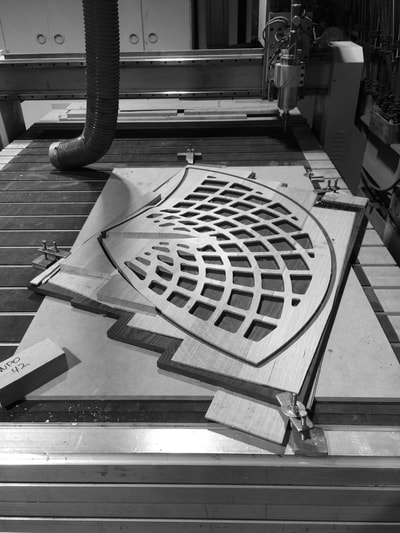

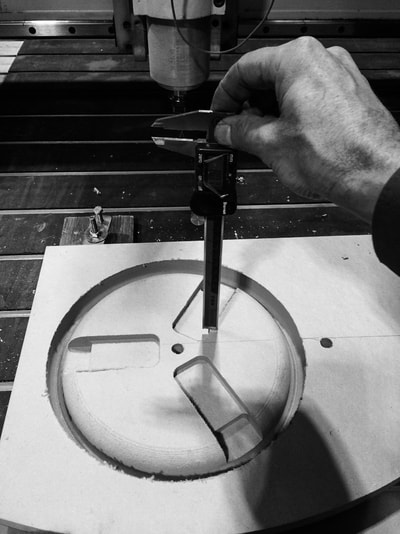

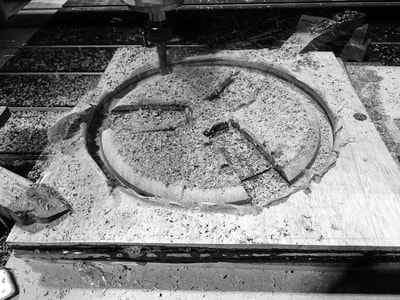

My current design interest is furniture which can be stowed or adjusted in some way, yet looks and feels like a quality crafted furnishing, unlike office furniture or plywood mass production product.. This circular table is an experimental prototype in many respects, in response to residential downsizing. This table can be quickly disassembled and reassembled into 7 light weight parts by a central knob allowing easy stowage and transport. It can also can be customized in height and style by component substitution, for example the height can be changed between a dining table and an occasional table. The use of Torrified timber as the core lamination capitalizes on its improved stability, while using a thinner lamination as a more suitable surface species. The lattice underneath reduces the weight of components. The use of computer aided design and numerically controlled machines feature in my craft work, alongside traditional techniques. This table was made for an exhibition.

This example uses Torrified American White Oak, in combination with Victorian Ash, both of which have FSC rating.

This example uses Torrified American White Oak, in combination with Victorian Ash, both of which have FSC rating.